Assessing brick production

Practical Action

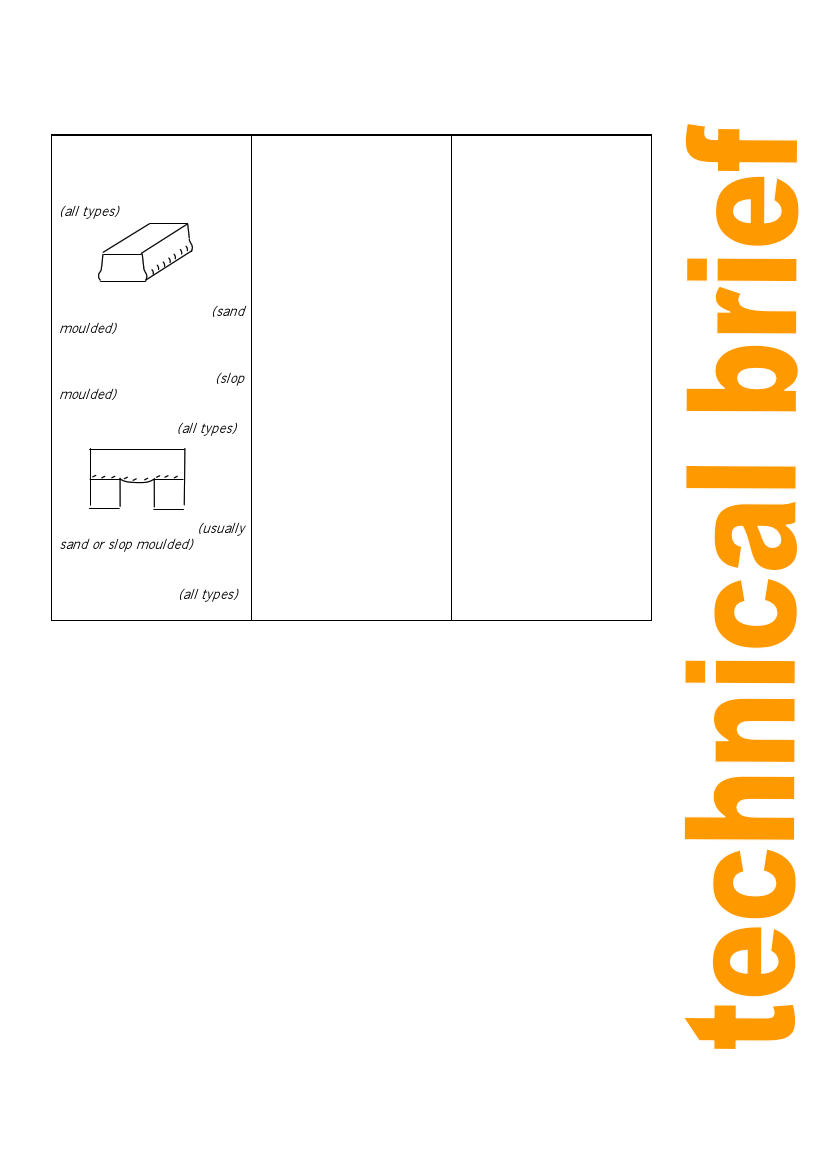

2. SHAPE

(a) Slumping - one stretcher

face is wider with a bulge

running the length of the brick

(all types)

(i) Too soft when moulded

(ii) Handling too rough

(i) Use a drier mix

(2) Take more care

(b) Rounded corners (sand Not enough clay pressed into Make sure mould box is filled,

moulded)

mould box, or rough handling or handle wet bricks more

gently

(c) Raised corners (slop Corners stick to mould when Use sand in mould or make

moulded)

brick is released

sure mould is wet enough

(d) Stacking marks (all types)

Bricks moved too soon from

drying singly on edge to

stacking

Make sure bricks are dry

enough before stacking

(e) 'Lips' or 'flashing' (usually Mould worn, clay 'seeps' out,

sand or slop moulded)

or moulder not 'striking off'

excess

Replace mould, or take more

care striking off excess flash

(f) 'Banana' shapes (all types) Top drying faster than bottom Gently turn bricks during drying

3